Say goodbye to tedious operations and welcome efficient gardening experience

Whenever the routine task of mowing the lawn is mentioned, the picture that comes to many people's mind is the picture of bending over to adjust the machine in hot weather. The traditional lawn mower head replacement process often involves multiple screw tightening links, and a little carelessness may cause Caton or even damage the equipment. Now, with the advent of a new generation of disassembly-free lawn mower heads, this kind of problem has finally been solved.

Why is frequent disassembly a workload?

Every time an old part is removed and a new part is loaded, it accelerates the aging of the part and increases the risk of accidental loss. Especially when faced with a large area of green space that requires continuous operation, such repeated actions undoubtedly greatly reduce the overall work efficiency and make people exhausted.

One-click facelift revolution without tools

Thanks to advanced engineering technology, the new disassembly-free structure allows users to complete the replacement procedure in a few seconds-just a light turn or push to lock the position. Even consumers who come into contact with such products for the first time can quickly master the skills and operate independently, eliminating the time and cost of looking for special wrenches and improving the convenience.

Learn more about the core benefits of this generation of lawn mower heads

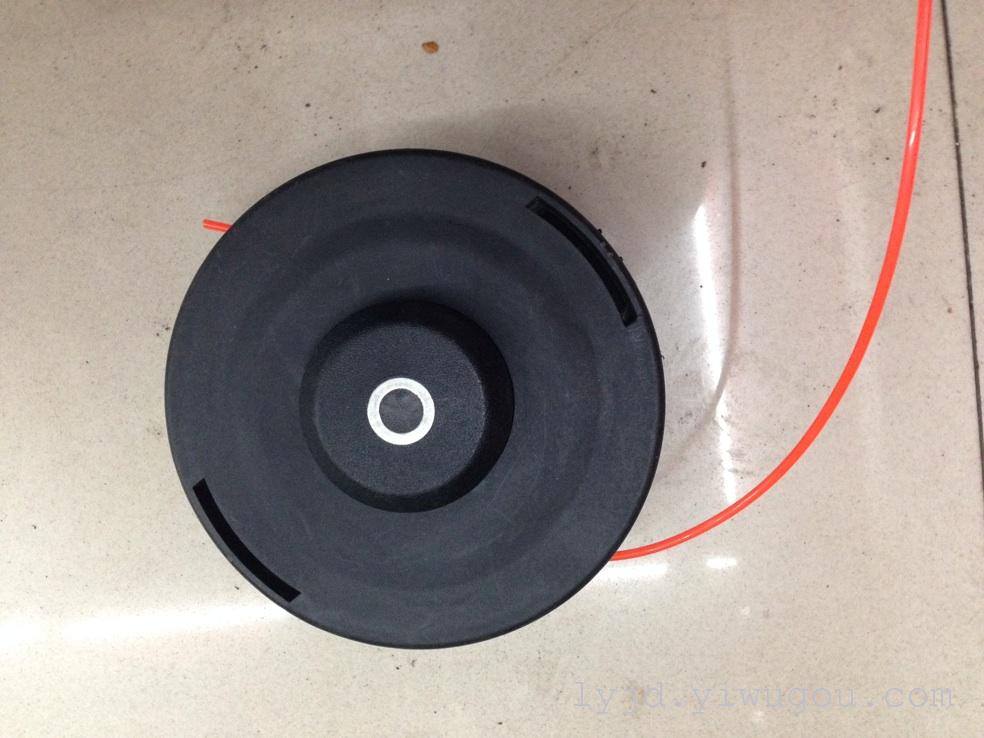

Despite the appearance of similar products, this small and exquisite device has many subtle ideas behind it. From infrastructure selection to grip comfort optimization, every step is carefully thought out to provide the best user experience.

Robust construction guarantees long-term stable operation performance

The body is made of high-density compression-resistant ABS polymer, which not only has a good shock-proof buffer effect, but also can resist the aging phenomenon caused by ultraviolet radiation. Even if exposed to the outside for a long time to withstand the test of wind, sun and rain, still strong as before, showing excellent durability quality.

Universal interface supports seamless cross-brand connection

in order to meet the diversified needs of consumers, the research and development team has specially formulated a unified specification connection module to enable it to smoothly connect to various power platforms of major well-known brands, including but not limited to electric drive and oil drive versions, greatly expanding its practical scope.

High-performance components work together to create extraordinary results

improving the main body alone is obviously not enough to form a complete solution. only by combining the surrounding related elements to form a joint force can we really stimulate the unprecedented strong performance.

Special fiber weaving process achieves strong cutting wire

professional grade nylon rope made of built-in composite reinforced polyester filament has the characteristics of super toughness and linear stiffness, which can always maintain a straight shape during high-speed operation, easily break through the boundary of thick and dense grass, and perform precise and detailed trimming tasks.

Excellent Adaptability in Diversified Application Scenarios

Whether it is the boundary modification of the flat open area or the cleaning challenge of the shrub forest area with a large inclination angle, the integrated system can quickly adjust its posture to cope with the changing actual situation by its highly mobile characteristics to achieve the desired satisfactory outcome.